Mechanical Engineering is a wide field with different areas of focus. Mechanical engineers can choose to specialize in specific areas.

Besides theoretical knowledge, practical knowledge is also important for mechanical engineers. Mathematics and Science are crucial subjects in the study of Mechanical Engineering.

The mechanical engineering interview can be challenging. It usually begins with basic verification questions and then progresses to technical questions.

These mechanical engineering interview questions will help you understand the types of questions you can expect and how to answer them.

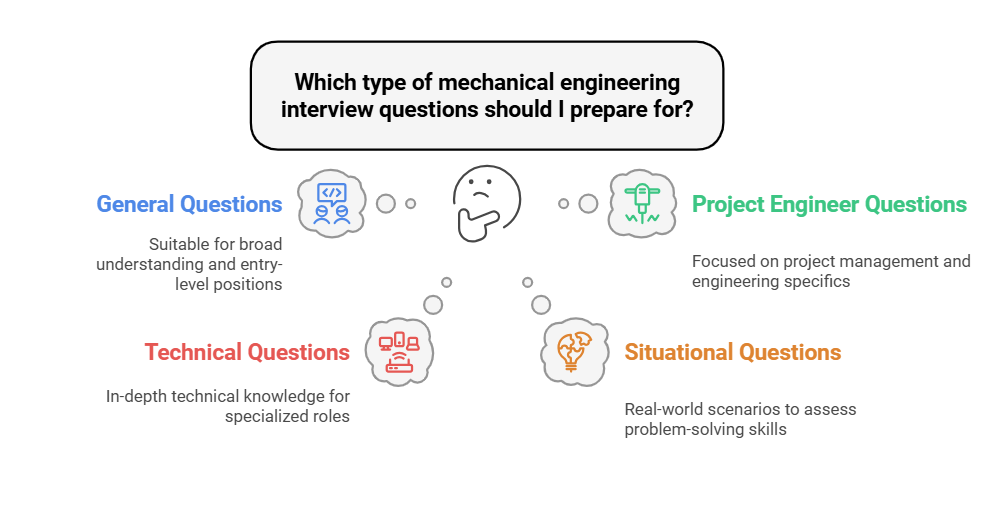

Types of Mechanical Engineering Interview Questions

Mechanical Engineering Interview Questions are categorized into 4 types :

1. General Mechanical Engineering Interview Questions

2. Mechanical Project Engineer Interview Questions

3. Technical Mechanical Engineering Interview Questions

4. Situational Mechanical Engineering Interview Questions

General Mechanical Engineering Interview Questions:

These mechanical engineering interview questions relate to your personal and educational life. They are also a way to test your communication skills.

1. Tell me something about yourself.

While answering this mechanical engineering interview question, try to be as natural as possible. Try not to repeat whatever is mentioned in your CV, as they already have your CV to refer to. Start answering this question by telling your name, as it is a general way to answer. Never sound as if you have learnt the answer (always learn the answer to this question).

Sample Answer: My name is Hrithik Shah. I graduated from college in 2020. I chose Mechanical Engineering as my career because, since childhood, I have been very fond of machines and how they work. I love researching machines and have done well during my college days, which is why I got an excellent internship opportunity that I just completed. This motivated me to look for a full-time job in a company where I will hone my existing skills and learn new ones.

2. Why do you want to work at our company?

Learn a bit about the company. While answering, don’t read the answer or let HR know that you have learnt the answer.

Carry out deep research about the company and mention unique points; a great way to get recent updates about a company is by going through their social media accounts. You can also add a personal touch to the answer, so you stand out among peers.

Sample Answer: This company offers me an excellent opportunity to explore and contribute to the industry. I am very well suited for this position because I am knowledgeable in this sector. I am well aware of your company’s production and its reach. After reading about this company in many articles, I thought how exciting it would be to work here. Moreover, the learning exposure is excellent.

Also Read: Mechanical Engineer Interview Questions for Freshers

3. Are you aware of the kinds of products our company makes?

You must have thorough knowledge about the company’s products. Think of each product conceptually and the subjects related to those products.

Sample Answer: Yes, I am aware that the company is involved in manufacturing rolling mills and is distributed in several top companies, which are spread nationally and internationally.

4. What were your grades during the course of study in Degree College?

Sample Answer: I consecutively received ___ CGPA during the first four semesters and ___ CGPA in the 5th and 6th semesters.

5. How many years did you take to complete mechanical engineering?

Sample Answer: It took five years to complete mechanical engineering, which includes one year of internship.

6. Which subject did you find the most challenging in the College?

The interviewer wants to get to know your preferences.

You could answer something like this:

Sample Answer: Power Engineering and Strength of Material were the most challenging subjects for me as I found the calculations and formulas very difficult to understand. There were many equations and derivations, which were challenging but once understood, it was fun.

7. Which was the subject you were most focused on?

Sample Answer: The most focused subject was engineering drawing, as it is the primary language of all the engineers and is the base of engineering study. Moreover, it is a document that transfers technical details and states the requirements. I have always been fond of geometry since school, and it is very necessary for the construction of a component.

8. What skills do you think a mechanical Engineer must possess to be successful?

The interviewer wants to get to know your point of view.

Sample Answer: Out of all the skills that a mechanical engineer must-have, the most important, in my opinion, is a problem-solving skill.

To solve a problem, that person should have the ability to see things from different perspectives and should be able to decide on what will happen. This also requires them to be innovative and try different techniques if one doesn’t work. Moreover, explaining ideas to another person who is not involved in that field can be tricky, so good communication skills are a must to become a successful mechanical engineer.

Also Read: Mechanical Engineer Job Description: Role and Description

Mechanical Project Engineer Interview Questions and Answers

9. What was your project during College, and how was your experience doing it?

Sample Answer: In college, I worked on a project to design and build a solar-powered water pumping system for rural irrigation. It was a hands-on experience where I learned a lot about teamwork, problem-solving, and applying what I’d studied to real-world challenges.

10. How did you carry out the design process?

Sample Answer: We carried out the design process in several key steps. First, we researched the requirements, focusing on the water flow rate, solar energy availability, and cost constraints. Next, we created detailed models using CAD software, iterating the design to optimize the pump’s efficiency and durability. Finally, we validated our design through simulations and prototype testing, ensuring it met both technical and practical needs before fabrication.

Technical Mechanical Engineering Interview Questions:

These mechanical engineering interview questions are more theory-related questions. They are meant to test your knowledge.

11. Can you explain to me what a cotter joint is and where it is used?

Sample Answer: A cotter joint is a straightforward way to connect two rods in a straight line for handling push or pull forces. It uses a flat, tapered pin called a cotter, which slides through matching slots to lock the rods together. You’ll see it in engines, machinery, and tension rods. It’s simple, reliable, and easy to take apart when needed.

12. How do pneumatics work?

Sample Answer: Pneumatics is an easy way of making things move by just using clean and dry air. It is used in factory automation systems as these systems use compressed air to create mechanical motion and power. The pneumatics use an air compressor and reduce the volume of air to increase its pressure. Then it is moved into a filter in pneumatic tubing, where it is controlled by valves before reaching an actuator.

13. How many laws of thermodynamics are there, and name all of them.

Sample Answer: There are three laws of thermodynamics.

The first law, also called the law of conservation of energy, says that energy cannot be created or destroyed in an isolated system.

The second law of thermodynamics says that the entropy of an isolated system never decreases.

The third law of thermodynamics says that the entropy of a system approaches zero as the temperature approaches zero.

14. What is a bearing, and where is it used?

Sample Answer: A bearing is a machine element that helps smooth motion between two moving parts by reducing the friction and constraining relative motion only to the desired portion. Nearly all the industries that use machinery and equipment have bearings in them. The most common example where bearings can be seen is in bicycles.

15. What is the difference between a pneumatic system and a hydraulic system?

Sample Answer: The main difference between pneumatic and hydraulic systems lies in the working fluid. Pneumatic systems use compressed air or gas, making them suitable for lighter, faster, and cleaner operations, such as in automation and packaging industries. On the other hand, hydraulic systems use pressurized liquids, typically oil, which allows them to generate much higher forces. This makes hydraulics ideal for heavy-duty applications like construction equipment, presses, and machinery requiring precision and power. Each system is tailored to specific operational need

16. What do you mean by case hardening?

Sample Answer: Case Hardening is a technique used to harden the surface of the metal while keeping the deep layer underneath to remain soft. It is done by infusing more carbon or nitrogen into the surface layer, thus making the metal more resistant and durable.

17. Is there any difference between an electric motor and an electric generator?

Sample Answer: Fundamentally, there is no difference between an electric motor and an electric generator. In our daily use, all motors work as generators, and all generators behave like motors. However, as the name suggests, an Electric generator generates electricity.

On the other hand, an electric motor uses electricity. Additionally, an electric motor transforms electrical energy into mechanical energy, and an electric generator transforms mechanical energy into electrical energy.

18. Which are some of the household devices in which electric motors are used?

Sample Answer: Devices that use electric motors are Water pumps, electric mixers, electric fans, MP3 Players and washing machines.

19. What do you know about spinning jenny?

Sample Answer: Spinning Jenny was invented by James Hargreaves. The purpose of this machine was to revolutionize the process of cotton spinning. By turning one single wheel, the thread was spun using eight spindles which made the work of the operator easier.

20. Can you explain how electricity is produced using coal power plants?

Sample Answer: Firstly, coal is grounded into fine powder by putting it in a pulverizer in a device called a boiler. Later it is burnt.

The heat which is produced by burning converts water that is present in the boiler to steam. The high pressure of steam turns the blades of a turbine. This results in the spinning of the generator and electricity is produced.

21. What is a Turboprop Engine?

Sample Answer: Turboprop is a word derived after combining the words “turbine” and “propeller”. A turboprop engine is a gas turbine engine that provides power to the propeller. It is usually seen in aircraft.

It works in the same way as a turbojet to manufacture energy by incorporating a combustor, compressor, and turbine within the gas generator.

It converts the bulk of its thrust into rotational energy. These engines are significant for safe and efficient regional travel.

22. How is iron ore turned into steel?

Sample Answer: In this process, the two main elements are iron ore and coking coal. Firstly, coking coal, iron ore, and limestone are combined to the blast furnace (metallurgical furnace used for smelting).During this process, heated air is blown into the base of the furnace to speed up the process of combustion.

This combustion of iron ore with other elements produces molten pig iron, which is later converted into steel. Limestone helps in capturing the impurities in the blast furnace.

23. Can you explain the working of concrete pumps?

Sample Answer: It uses a valve system to run smoothly and some basic principles of hydraulics. The mixing truck mixes the concrete in its rotating drum and makes it in a liquid state.

The liquid concrete is then poured into a hopper, and the hopper continues to churn it so it does not get into the solid state.

Later, the concrete pumps suck the liquid concrete out of the hopper through the valve system, and it is then laid down in the area where it is required.

24. What is the density of plastic?

Sample Answer: This mechanical engineering interview question has many possible answers as there are different types of plastics, and all of them have their different density. It is calculated by dividing the mass of the product by its volume.

25. What is Orthographic Drawing?

Sample Answer: Orthographic drawing is a presentation of three-dimensional objects as two-dimensional objects. It is a form of parallel projection in which the lines are orthogonal to the projection plane. It shows the objects from all sides as it is seen in a three-dimensional object.

This is useful to see the hidden details and connecting parts that are difficult to notice in a three-dimensional object, making the manufacturing process more manageable and effortless.

26. What is a feasibility study?

Sample Answer: Feasibility study is a way to recognize what the market needs or the business to be undertaken according to the wants and needs. It helps in determining if a business opportunity is possible, practical and viable and grabbing it. It gives a realistic view by identifying both the positive as well as negative aspects of the study.

27. What are the advantages of Gear drive?

Sample Answer: Gear is a machine component with multiple advantages because of its ability to transfer mechanical power from one shaft to another.

– It is helpful for compact construction as the centre distance between the shafts is relatively tiny.

– It is highly efficient.

– It works well even at low speed.

– Its size is very compact in construction.

– Its velocity ratio always remains constant as it is used for positive drive.

– They have good longevity.

– Maintaining it is very easy as it only requires lubricant to ensure its smooth running.

28. On what parameters are screws classified?

Sample Answer: Screws are classified based on the following parameters:

– Screw Head

– Screw Thread Type

– Screw Drive Type

29. Which are the different types of screws, and what are their uses?

Sample Answer: There are many types of screws:

– Wood screws made up of bronze, brass, or steel are used while working with wood.

– Drywall screws are used for drywall panels. These come in two types- W-type screws and S-type screws.

– Self-tapping screws- These screws can work as drywall, wood or metal sheet screws. They can be used without a drill.

– Metal sheet screws are universal screws that can be used anywhere, whether joining rubber, plastic, metal or plywood.

– Masonry screws need pre-drilling as they do not have a pointed end.

30. What is a moment of inertia?

Sample Answer: The moment of inertia is also commonly known as mass moment of inertia, angular mass or second moment of mass.

It is a quantity that estimates the torque required for angular acceleration and how far it can resist. It is derived by the addition of products of the mass of each particle in the body and the square of its distance from the axis of rotation.

Also Read: How to Write a Mechanical Engineer Resume?

31. What rules are required to be followed to have good quality castings?

Sample Answer: Following rules are essential and should be kept in mind to have a good quality of castings.

– Make sure the thickness is minimal so that the flow of materials is smooth.

– Keep the casting as simple as you can.

– The sharp corners should be avoided.

– All the sections must be kept uniform as much as possible.

– Webs and ribs should be kept minimum.

32. What is Geometric dimensioning and tolerancing?

Sample Answer: Geometric dimensioning and tolerancing uses a symbolic language on engineering drawings and solid models that are three dimensional.

It helps the manufacturer be precise and accurate while manufacturing machines on each controlled feature of the part. It helps determine the size of every individual feature and location in between them.

33. What are the different types of fits?

Sample Answers: There are mainly three groups in fits:

– First is a clearance fit that allows for loose mating where free movement is necessary. This is used where the elements are required to be able to slide in swiftly without any obstruction.

– Second is the Interference fit which is relatively tighter than a clearance fit. It requires some amount of force to join two components.

– The third one is the transition fit which falls between clearance fit and interference fit. These are used when accurate alignment is essential, and mating parts need great precision while joining.

34. What is mechanical refrigeration?

Sample Answer: Mechanical refrigeration is a process in which heat is extracted from a location using the man-made heat-exchange system. This system of refrigeration could be non-cyclic, cyclic, magnetic or thermoelectric. It depends upon the application for which there is a need for refrigeration.

35. What is Knurling?

Sample Answer: Knurling is a process of manufacturing conducted on the lathe, and a pattern of angled or crossed or straight lines is pressed into the material.

Situational Mechanical Engineering Interview Questions and Answers

For these types of mechanical engineering interview questions, the interviewer wants to see how you will behave in a particular situation.

36. If you cannot get the desired results from a prototype, what will be your next move?

Sample Answer: As we all know, prototypes are meant to be for trial and error purposes, so I cannot expect it to work just fine on the first try.

Testing it and fixing the problem, and later seeing that my design has been functional is what will make me happy. I enjoy applying my theoretical knowledge as I have a focus on it a lot.

37. In case there is a need to work under pressure and rotational shift timing, will you be able to handle it?

Sample Answer: Yes, being in this industry has trained me well to work under pressure. The study part was not easy, and there were times when I worked day and night brainstorming on a particular project.

Also, this industry demands flexibility to work in different shifts, and I am prepared for it.

38. How will you describe your design from a person that does not belong to your industry?

Sample Answer: Whenever there is a situation of explaining the design to someone who is not from mechanical engineering, I try to avoid using the technical language as much as possible.

If there is a need to use a technical term, I will make sure the person knows what that word means.

It is very important for the person to know the exact purpose of the design and its wonders. Moreover, I will answer any of their questions very happily; this also shows how much they have understood what I am saying and explain it again if needed.

39. Tell us your experience when you worked on an engineering project that failed.

Sample Answer: While answering this mechanical engineering interview question, give examples from your experience. I was working in a team of six when we had to design a wheelchair for disabled patients, which would make the work of pushing it easy for the staff.

We just had to make changes to the outdated wheelchairs being used. We were ready with a prototype that could serve the purpose but later got clear instructions that this wheelchair was for transporting obese patients.

We then had to start from scratch, which took a lot of time and increased our cost. The next time we made it, we decided to work on an assumption basis and ask too many questions to ensure the purpose and use.

40. Is it okay to use motor oil in a hydraulic system? Would you please justify your answer?

Sample Answer: No, motor oil cannot be used in a hydraulic system as motor oil runs at a very high temperature, and hydraulic oil will start to fail at 45c.

Once the hydraulic oil is run over this heat for an extended period of time, the oil will burn. This will lead to small particles stuck in the filters, which will trigger the pump to cut out. The filters will have to be changed, which will make it a costly job.

Pro Tips on How to Answer Mechanical Engineering Interview Questions

Here are some tips that you must keep in mind:

- The general mechanical engineering interview questions must always be learnt, and you must practise speaking them as naturally as possible.

- Be confident while speaking. Don’t get nervous as it affects your speaking tone.

- The technical mechanical engineering interview questions must be answered in a way that is easily understandable by the interviewer.

- Lastly, Dress appropriately in formal attire.

Also Read: Engineering Interview Questions & Answers for Freshers

Conclusion on Mechanical Engineering Interview Questions

The most important part of a mechanical engineering job interview is knowing the technical questions. It can come from theory or practical as both are equally important.

The degree of mechanical engineering interview questions and answers is much higher than other interview questions, as the basics of technicality are essential.

All these elements with a person loaded with confidence will help you get through. Mechanical engineering, although difficult, is a great field to make your career in.

With an understanding of machines comes fun exploring how things work and on which principle these incidents and machines are used in our daily life.

| Related Topics | |

|---|---|

| Fresher Mechanical Enigneer Jobs | Mechanical Engineering Jobs |

| Remote Mechanical Engineer Jobs | Mechanical Design Engineer Jobs |

Job By Role: